Bamboo is a renewable resource that has become one of the most important alternatives to tropical hardwoods in recent years. When you see bamboo flooring, kitchen cabinets or cutting boards, you may have wondered how round, hollow bamboo logs are made into solid bamboo panels? We have explained a lot in a previous blog, in this blog we will talk specifically about bamboo composites.

First of all, it is important to know that solid bamboo panels can be divided into two main groups: "laminated bamboo" and "bamboo composite" (or a combination of both). Semi-finished products such as OSB, MDF, particleboard, plywood, woven mats, etc. can also be made from bamboo fibers or bamboo chips, but panels composed on the basis of bamboo strips (laminate) or bamboo strands (composite) are by far the most commonly used in Europe. In the previous blog, it was explained how the normal board material is made. In this blog you can see how composites are made.

With composite bamboo, the same steps apply as with laminated bamboo, except that the strips are not glued together horizontally or vertically. Instead, raw bamboo strands are used and pressed together under very high pressure to create a new "composite."

The density of bamboo composite panels is greatly increased (from 700 kg/m3 to over 1200 kg/m3) compared to laminated bamboo. As a result, bamboo composite is also much harder than laminated bamboo with a Janka hardness of 2800 lbf instead of 1380 lbf.

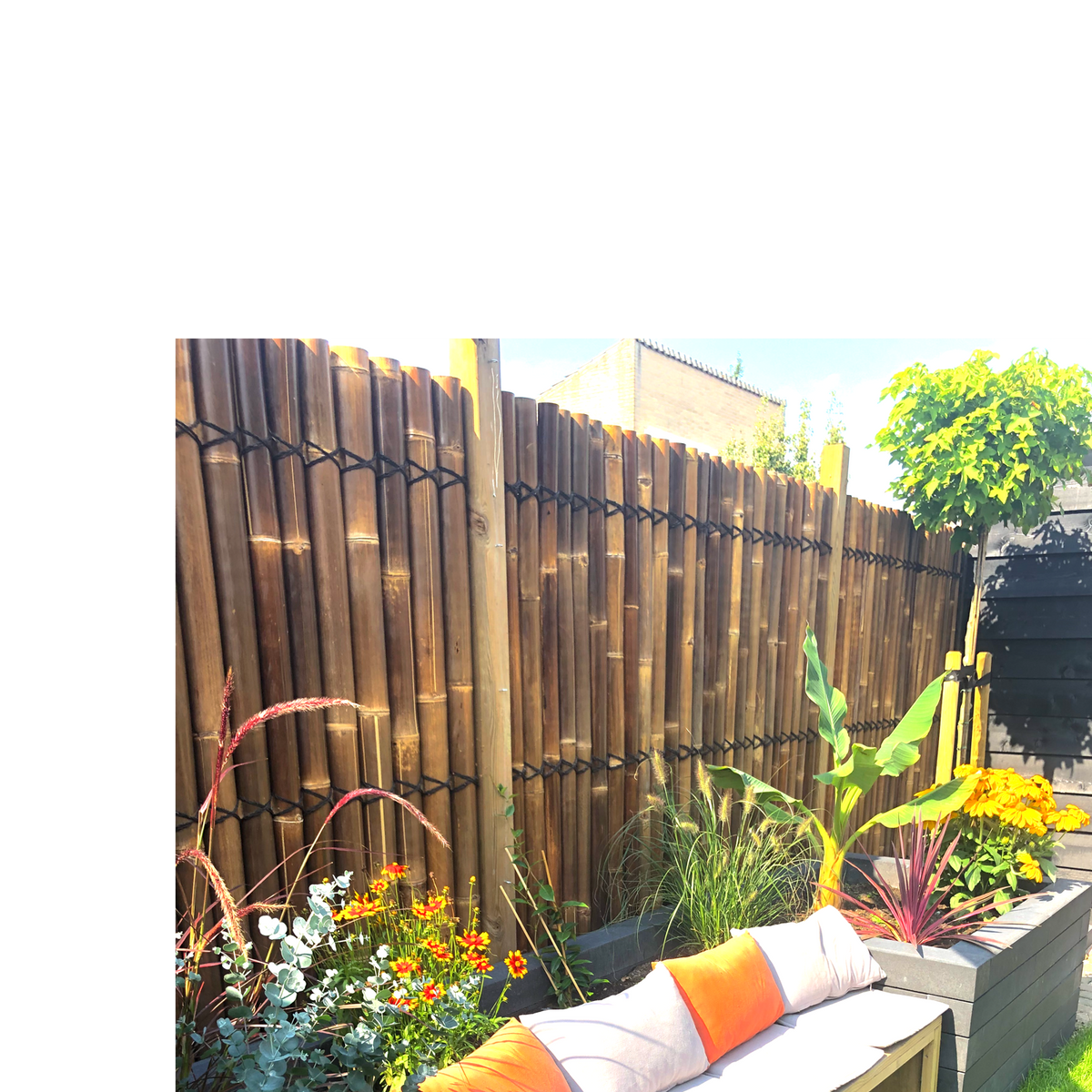

The appearance of bamboo composite is completely different from laminated bamboo. Bamboo composite looks more like wood with its mottled texture, and the bamboo knots have become almost invisible.

Step 1. From strips to strands

After boiling or caramelizing the bamboo strips as described in steps 5 - 6, the strips are broken in this special machine to produce coarse-grained strands.

Step 2. impregnation of the bamboo strands.

Just before pressing, the bamboo strands are impregnated with glue. Impregnating

Impregnating

Step 3. Pressing

The bamboo strands are then placed in a huge press and pressed into panels at a pressure of 2,500 tons. Sawing

Sawing

Pressing

Pressing

Step 4 Sawing

Bamboo composite boards are available up to a maximum thickness of 20 mm. Since they would otherwise be much too heavy, the 30 - 40 mm thick panels are sawn into narrower boards 10 - 30 cm wide. These in turn can then be made into bamboo flooring, decking or cladding, for example.

Are you also interested in working with bamboo boards? Then order your bamboo boards in our webshop today!