The mechanical properties of bamboo

What are the mechanical properties of bamboo? This is probably one of the most frequently asked questions by architects, engineers and builders interested in using bamboo as a building material. The material properties of wood, steel, concrete, and even semi-finished bamboo products such as flooring and bamboo panels have long been known, but not those of bamboo canes. And why?

"The strength properties of bamboo are often two to three times better than those of conventional wood. However, legal uncertainties regarding building codes and standards make it difficult to use bamboo poles as a building material in Europe."

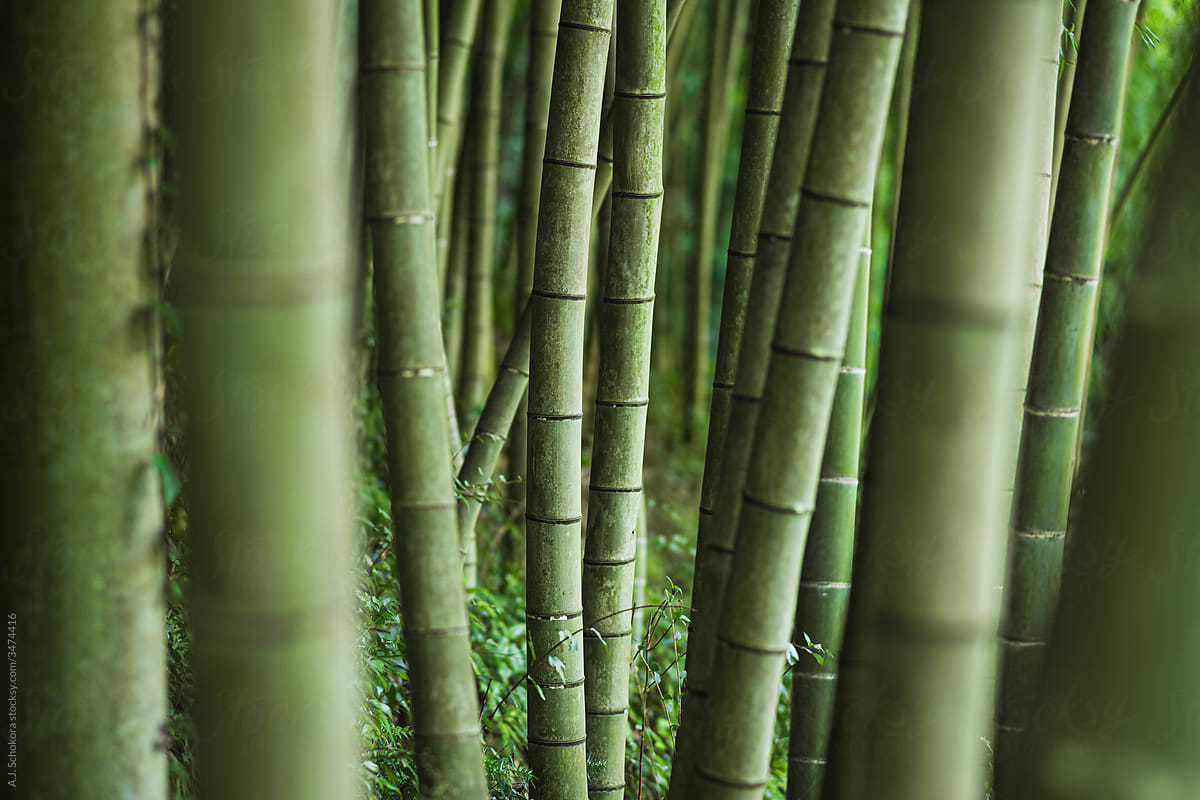

Bamboo is a collective name for more than 1575 different plant species that belong to the grass family (Gramineae). Each of these bamboo species has different structural and mechanical properties, just like conventional wood species such as teak, oak, etc. In addition, the mechanical properties of a single species of bamboo can also vary greatly. These differences are due to the age of the bamboo trunk, moisture content, growing conditions (climate, altitude, soil conditions) and the part of the bamboo trunk on which the tests are performed.

Since the most suitable bamboo species for construction purposes come from tropical countries, it is often difficult to determine the exact growing conditions and obtain good test material. As a result, different studies often come to different conclusions, which means that the behavior of the material in certain situations is not yet completely certain.

Why are

mechanical properties important?

In Europe, there is still no standardization (Eurocode) for bamboo canes as a building material. The lack of such a building regulation for bamboo makes it difficult for those who want to build with this material, so there is an urgent need for clear rules and standards.

The tests already conducted on the compressive, tensile and flexural strength of bamboo are promising and generally show much better results than conventional building materials. However, there are other factors that need to be investigated before a legal building code can be issued for bamboo piles as a building material

Other

Mechanical properties

These other properties are:

- Durability

- Fire safety

- Environmental sustainability

- Ease of use

- Energy efficiency

More research is needed, particularly in the areas of fire resistance and durability. Nevertheless, significant progress has been made in recent years with the introduction of the international standard ISO 22157.

Bamboo

Tensile strength

Bamboe strips

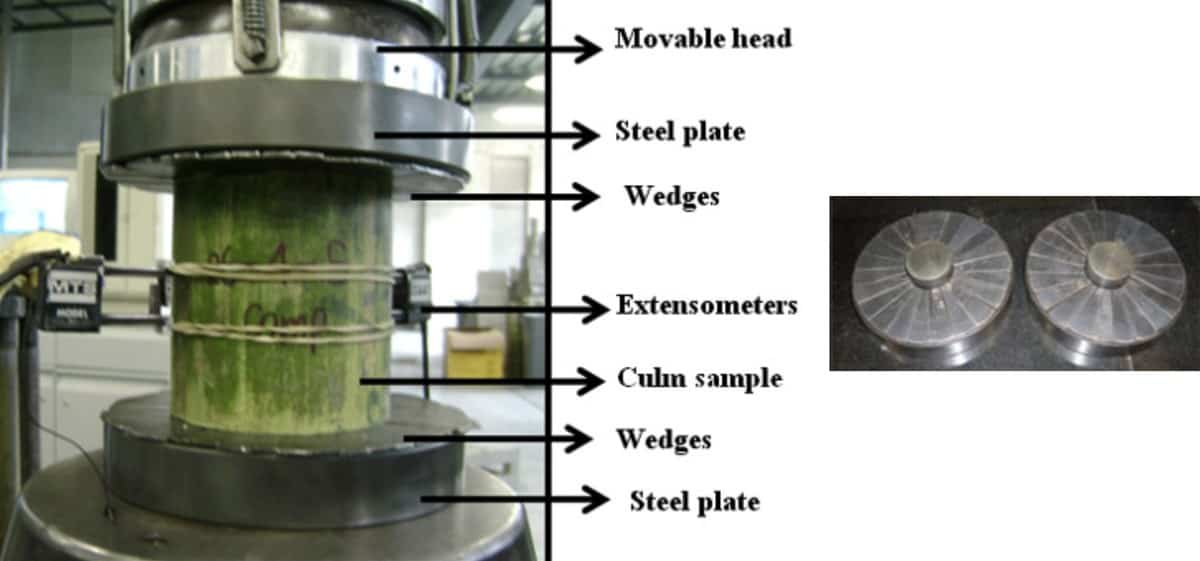

The maximum tensile strength of bamboo is determined by testing the fibers (bamboo strips) rather than the entire bamboo stem. As with compressive strength, the ISO 22157 standard provides guidelines for tensile strength parallel to the grain direction, but not for tensile strength perpendicular to the grain direction.

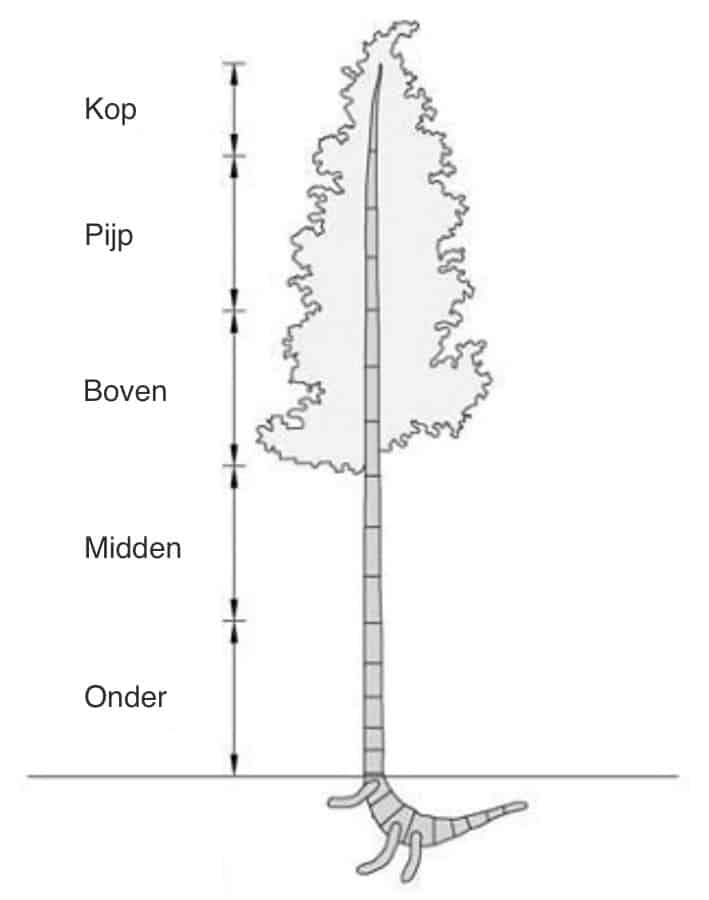

Samples

To measure the tensile strength of bamboo, three specimens are tested per bamboo log, taken from the lower, middle and upper parts of the log. Each bamboo strip is 100 mm long, 10 - 20 mm wide, and the thickness is equal to the thickness of the bamboo stem.

Knot

Each sample should contain a knot because the direction of the knot's grain is opposite to the direction of the stem's grain. Therefore, the knot is considered to be the weakest point under tensile loading (for compressive strength testing, it is the other way around). The moisture content of each of these test specimens should also be determined according to the ISO 22157 standard.

Conclusion

The average tensile strength of the various bamboo species is, for the most part, 160 N/mm2. This is three to four times higher than the tensile strength of most commercial wood species.

Bamboo

Flexural strength

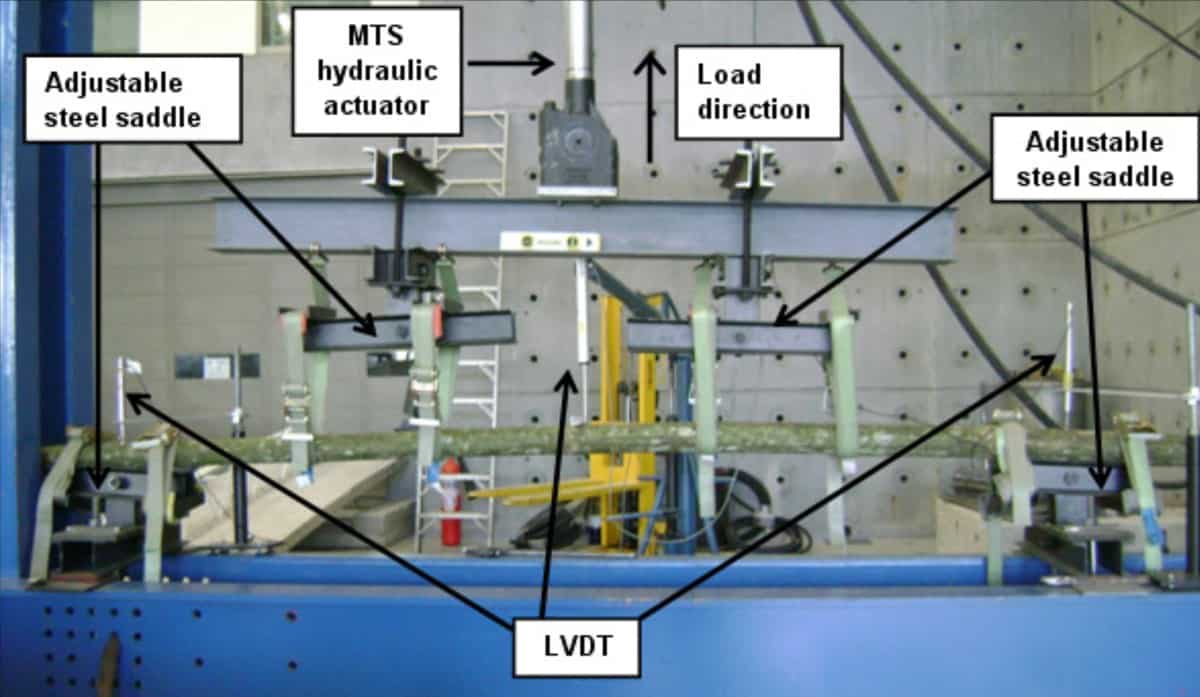

The deflection of a bamboo stem has a direct influence on the behavior of the built structure. Therefore, it is necessary to be able to predict the deflection of each element of a structure before it is used. The most common method for determining the deflection of a beam or column is the four-point deflection test. Therefore, the ISO 22157 standard suggests this test for determining the bending strength of a bamboo log.

Bamboo

Bending strength of Guadua Bamboo

The four-point bending test prescribed in ISO 22157 was conducted at the University of Los Andes in Colombia. The bending test was performed on the same bamboo logs as the compressive and shear strength tests.

The four-point bending test determined the modulus of elasticity and, of course, the flexural strength. The results of this test are shown in the table below.

The modulus of elasticity of Guadua angustifolia is highest in the lower and middle part of the trunk, and this is when the trunk has an age of 4 - 5 years. This is not the case for the upper part of the trunk, where the highest modulus of elasticity is obtained when the trunk has an age of 3 - 4 years, just like when the modulus of elasticity is determined in the compression test.

Also, the bending strength of the bamboo log is not the same for all three parts, the upper part of the bamboo log has a greater bending strength than the lower part. The bending strength increases with the height of the trunk. The bending strength of Guadua angustifolia is about 100 N/mm2.

Bamboo

Comparison of bending strength of different bamboo species

The bending strength of Guadua angustifolia is in the same order of magnitude as the bending strength of other commonly used bamboo species. The following table gives an overview of the bending strength of some other bamboo species. Not all results were obtained using the four-point bending test as prescribed in the ISO 22157 standard. Therefore, these values may have a small variation, but they give an idea of the magnitude of the bending strength of different bamboo species.