Bamboo Import Europe

Bamboo Slat Dark

Pay securely with:

We deliver your order together with our partners

Bamboo Laths Black are made from the Indonesian bamboo species Java Back and have a beautiful black, brown colour. These 4 cm wide slats are available in various lengths and are supplied untreated. These slats are perfect for cladding walls and ceilings, as they are beautifully flat at the back, weigh less and take up less space than full bamboo poles.

Bamboo Slat Dark

WORKING WITH BAMBOO

Bamboo laths can be glued with waterproof wood glue or screwed. When using screws, we recommend always pre-drilling to minimise the risk of cracks.

Cutting bamboo is best done with a Japanese saw. This special bamboo saw has small sharp teeth that allow you to cut easily, quickly and precisely.

FEATURES

Each bamboo slath is unique. Colour differences and variations in thickness are normal for this natural product.

What can you buy from Bamboo Import?

- Bamboo Fence Rolls

- Bamboo Fences

- Bamboo Pergolas

- Thatched Roofs

- Reed Fence Rolls

- Willow Fence Rolls

- Bamboo Borders

- Bamboo Blinds

- Bamboo Furniture

- Bamboo Flooring

- Bamboo Decking Board

MAINTENANCE AND CLEANING

After installing the Bamboo Lat Black, you can apply our Bamboo Protector. A specially developed colorless/transparent stain that protects the bamboo from tarnish and discoloration. With outdoor use bamboo will gray and discolor, just like any natural material. We therefore recommend to treat bamboo annually, preferably in spring, with our Bamboo Renovator Dark, a specially developed stain that protects the bamboo and restores the color. Bamboo Renovator Dark is easy to apply to cleaned bamboo using a brush. Use thin layers and spread the Bamboo Renovator Dark well. To clean bamboo you can use our Bamboo Cleaner. Possibly in stubborn dirt / deposits bamboo can also be sprayed off with a high pressure cleaner. But at an appropriate distance to avoid damage.LOOKING FOR A SHINY RESULT

An alternative maintenance product is also available. That is Bamboo Booster. Bamboo Booster is a natural oil that can be easily applied with a cloth. With this oil you get a nice shiny result. The oil protects and nourishes the bamboo, but does not slow down the process of discoloration.Bamboo Booster can be applied several times a year for optimal results. The oil can only not be combined with our Bamboo Protector and Bamboo Renovator Dark stain.

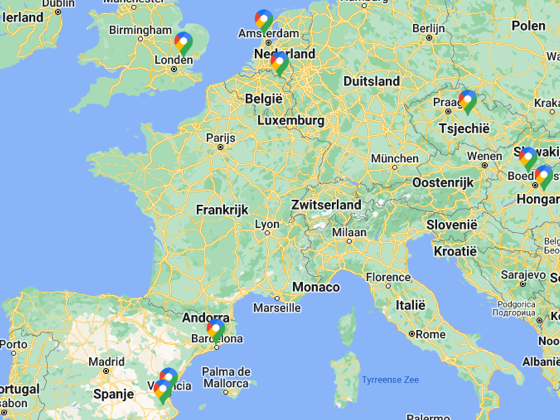

Sustainability is very important to us. That's why we also want to be transparent when it comes to shipment costs. We do not make a profit on the total shipment costs to our customers.

Small items/quantities are shipped from € 6,99

Medium items/quantities are shipped from € 15,99

Large items/quantities are shipped from € 49,50

For a complete overview of shipping costs and delivery times, please see the overview page.

Subheading

Bamboo Benefits

With photosynthesis, bamboo extracts CO2 from the air and releases oxygen. Bamboo produces about 40% more oxygen than wood and absorbs up to 35% more CO2 than wood. That makes bamboo better for CO2 offsetting than wood.